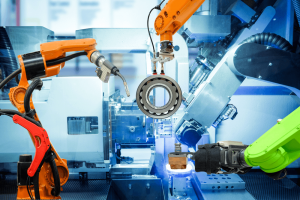

Collaborative robots (or cobots) are becoming an increasingly useful tool for manufacturers hoping to optimise speed and efficiency on the assembly line. Indeed, cobots are great for taking over repetitive tasks from humans, completing them to a high degree of accuracy and in a way that saves time. To help you understand why this is, we’ve put together some of the advantages of using a cobot when it comes to product assembly.

The future of product assembly

Many manufacturers are investing in cobots now in order to future-proof their businesses. This is because cobots are becoming increasingly normalised across a number of industries. In many ways, the mass adoption of these helpful robots has been inevitable since their arrival on the market. They are easy to use, with a number of models offering programming options for virtually any manual task, including those with quick change-overs or small batches. Robots can also save previously programmed tasks on their systems, allowing for their accurate replication on a regular basis.

Cobots offer a wide range of automated assembly options

Cobots are offering an increasingly sophisticated range of assembly options, meaning that manufacturers across a wide range of industries are able to use them on their assembly lines. This includes businesses working with a vast array of materials including plastics, woods, metals, and much more.

Cobots can assemble products safely alongside humans

Traditional product assembly carried out by humans often comes with certain risks thanks to the necessary use of heavy machinery. Fortunately, cobots can eliminate this risk thanks to their inbuilt safety technology. Indeed, cobots can detect humans within close proximity and are able to halt tasks immediately if they detect that a person may be in danger. When the person leaves the room, the cobot will automatically take up its task again.

Cobots actually improve quality and consistency

Assembly by regular employees usually means that quality and consistency will differ between items. Human error is only natural, after all. By enlisting a cobot, you can boost the consistency, quality, and speed of your assembly very easily.

Cobots can save space and flexibility

Assembly lines can sometimes be crowded and uncomfortable. Fortunately, cobots tend to be as small and lightweight as possible, giving your human employees a more pleasant working environment.

Cobots can adjust their assembly output in accordance with changing consumer needs

Many companies experience fluctuations in demand, with certain seasons requiring a higher assembly output. Cobots can be adjusted to ensure that the needs of your customers are met and resources are not wasted.

Click Buttons Below to Read More

Click to Learn About Robot/Cobot Hire in the UK.