Collaborative industrial robots often function from a fixed mounting, but there is an increasing demand for mobile industrial robots that association with a mobile based and a cobot.

Collaborative industrial robots are tools designed to support to support human workers in their work, relieving employees of many heavy, tedious and unergonomic tasks such as holding a heavy part steady in the needed position where human workers are to fit screws.

Collaborative industrial robots help manufacturers to improve on their productivity by using robots instead of human workers to complete industrial tasks.

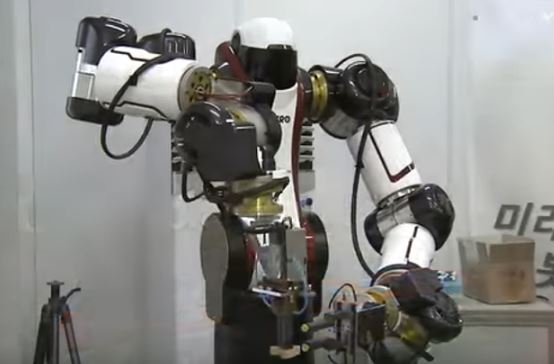

Collaborative robots stand in contrast to traditional industrial robots, which are intended to function separately with protection assured by separation from social links. With sensors and other design features such as rounded edges and lightweight materials, collaborative industrial robots can interrelate directly with humans.

Service robots, which are for domestic and professional use, can be considered to be collaborative industrial robots as they are planned to function together with humans. Collaborative industrial robots can perform many functions, and it can be used to power repetitive and tasks that are not ergonomic such as fetching and carrying weighty parts, machine feeding, and final assembly.

Collaborative industrial robots enable electronics manufacturers to extend robotics to final finishing tasks and quality inspection. Collaborative industrial robots when working together with human workers can quickly learn tasks through demonstration and support of learning.