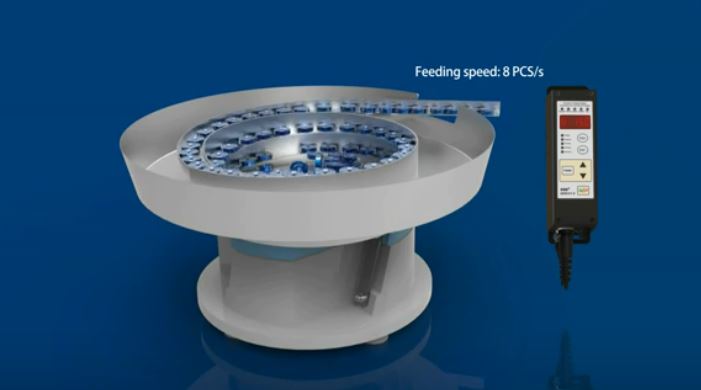

Vibratory bowl feeders are designed drying, screening, cooling used in feeding separate component part for gathering on industrial manufacture line. parts feeder base, hoppers, orienting rolls, centrifeed units frequently require some means to control their vibration. Therefore, without vibratory bowl feeder controller all the feeder components will function at their maximum speed. For most vibratory bowl feeder controller applications, a variable controller is needed to compensate for variations in machine sequence rates.

Vibratory Bowl feeder relies on the mechanical behavior of a portion, in such a way that when it’s lightly shaken down a conveyor chute that is fashioned to fit the part, they will progressively be shaken so that they are all connected. With the increasing incorporation in the entire manufacturing process, the need for vibratory bowl feeders is from time to time reduced by providing the mechanisms on tape packages that keep them oriented the same way throughout shipping and storage. Vibrating conveyors is made up of vibration damper, vibration motor, support base, trough and other accessories.

Vibratory Bowl feeder’s controller are used by many manufacturing companies such as cosmetics, pharmaceutical industry, electronics, automotive, food, Fast Moving Consumable Goods, packaging, and metalworking companies. It also serves other businesses, including construction, foundry, steel, glass, recycling, paper, and plastics. It also provides a cost-effective substitute for physical labor to save manufacturers labor cost and time. Many factors must be put into consideration when choosing a parts feeder, such as the industry, material properties, application, and product size.