Table Top Baggers

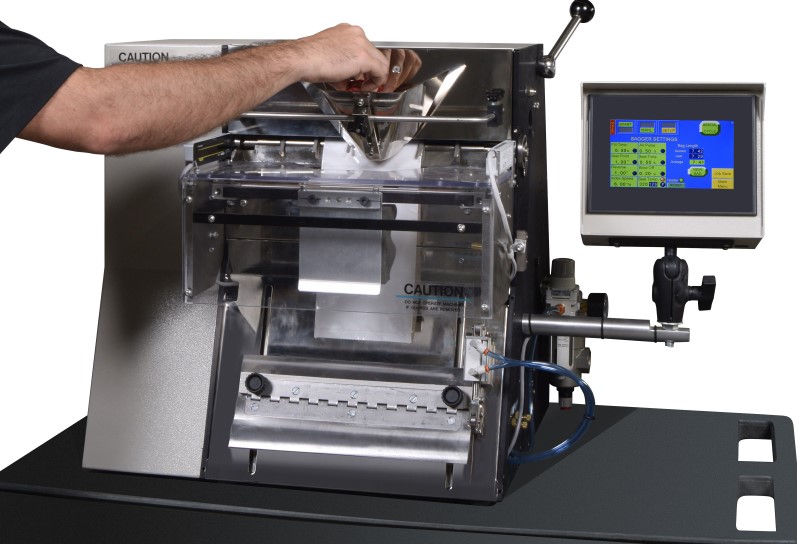

T-300 Bagging Machine

Despite being our smallest fully automatic bagger, the T-300 is packed with great features to help make light work of production. These include touchscreen controls with pop-up messaging, job memory and recall when you need to return to a project later, and the ability to add automatic infeed equipment. It can be used with automatic indexing and sealing tools and can create tear-off or continuous strips of bags.

T-375 Bagging Machine

The T-375 model has all the same features of the T-300 but also includes thermal transfer printing as an option. This patented feature lets you print just prior to loading the bag, so you know it’ll be correctly labelled with the right product. This lets you package quantities of just one part number.

Features:

• Four colour touchscreen with pop-up messaging

• Troubleshooting and diagnostic options

• Bag counter – pre-sets and totalising

• Automatic operation with delay time to allow for filling

• Universal, adjustable chute for parts

• Adjustable support shelf

• Bag inflator with flow controls

• 1-year limited parts warranty

Description

• Seal mechanism: 1/8″ Solid heater bar

• Cycle operation: Automatic paced

• Bag size range: (10″ rolls) 2″ x 2″ up to 11″ x 16″

• Guard-switch feature: Standard

• Product pass-through: 2-3/4″ (can be increased)

• Electric: 240V/60Hz

• Air: .50psi

• Dimensions: 20″ W x 14″ D x 21″ H

• Weight: 110 lbs/125 lbs.

T-275 Bagging Machine

The T-275 lets you package products quickly by taking away a lot of the work. It’ll automatically feed a bag into the loading position and blow it open, leaving you free to insert your product. Press the guard switch or foot switch and the bagger will seal the bag, and feed the next one into position ready for you. You can also set it to an automatic paced rate, and it features a total cycle counter to help you track rates. It’ll also remember the set points you configure and recall them when switched back on.

Features:

• Heat seal bar with adjustable temperature

• Patented Teflon shield to protect Teflon when in use, minimising burn

• Guard Switch operation to minimise the operator’s movement, reducing their fatigue

• Patented anti-jamming tech automatically reverses seal bar when needed

• Universal funnel included

• Air knife blows open bags quickly

• Adjustable supports allow for heavier products

• Simple threading system

Description:

• Bag feed method: Automatic registration

• Seal mechanism: Solid heater bar, continuous heat

• Cycle operation: Automatic

• Bag size range: 2″ x 2″ up to 11″ x 16″

• Film thickness: 1 to 5 mil

• Estimated speed: 10 to 25 bag/min.

• Guard-switch feature: Standard

• Auto/Paced rate operation: Standard

• Anti-Jam seal bar: Standard Safety Feature

• Electric: 240V/60Hz

• Air: .5cfm/40psi

• Dimensions: 19-1/2″ x 16″ x 21-1/2″

• Weight: 60 lbs.

Production Baggers

T-1000 and T-1000W Bagging Machines

Our top-of-the-range model, the T-1000 Advanced Poly-Bagger is perfect for long or short bagging runs, being capable of over 100 bags per minute and therefore much faster than a manual operator could ever be. It is ideal for use with automatic infeed equipment such as vibratory bowl counters or scales, and it can work in tandem with punch/stamp presses, blister machines, and other continuous manufacturing equipment, great for making bagging part of an in-line process.

Features:

• Easy-to-use touchscreen controls with up to 30 pre-set programmes and adjustable arm and bracket

• Patented Teflon Shield protects Teflon from the heater bar to extend its life

• Works with Advanced Poly-Bags

• Easy to manoeuvre around your business if required

• 1-year parts warranty, but crafted from high-quality materials for a long life

• Automatically turns off components when not in use to extend their life

• Four counters help you monitor productivity, track when an order is complete and maintain the machine long-term

• Anti-jamming device prevents dangerous clogging

• Troubleshooting included to maintain efficiency

• Works at high speeds, over 100 bags per minute

• Versatile enough to bag almost any product and great for short or long bagging runs

• Built for reliability

• User-friendly interface ensures complete simplicity

T-1000H & T-1000H Wide Bagging Machines

The T-1000H is a horizontal bagger, perfect for any products that may be difficult to bag on a typical vertical loader. So if you’ve got product manuals, folded clothing, coils of rope or cables etc., you don’t need to worry about gravity causing your products to be bagged messily.

It works either manually, if you want to slide your product into bags, or it can run automatically. The product is bagged automatically and pushed along a conveyer belt or into a bin, with the next bag placed ready into position, inflated and waiting.

Features:

• Adjustable angle to suit your products

• LC-10 Light Curtain safety feature included as standard

• Great for quality checking, as it is designed for close viewing

• Patented ‘Next Bag Out’ printing stops bags from being mislabelled

• BO-30 Bag Opening ensures each bag is ready for your product

• Intuitive touch panel controls with troubleshooting and up to 32 pre-set programmes you can save

• Solid bronze heater bar with Teflon Shield and anti-jam technology for safe, efficient and long-lasting sealing

• Works with products up to 8” thick

• Compact design helps it fit into your manufacturing process with ease

• Stainless ‘Slide’ plate offers low friction for ease of use

Description:

• Weight: 282 lbs. 332 lbs.

• Dimensions: 36″ width x 81″ long

• (including 3′ conveyor) 47″ width X 93″ long

• (including 4′ conveyor)

• Memory: 32 job saves

• Load Height: 40″

• Cycle Rate: 100 bags/min.*

• Seal Bar: 15″ wide bronze

• Bag Size: Minimum 3″ x 5″ 4″ x 7″

• Bag Size: Maximum 14″ x 30″ 18″ x 30″

• Product Pass Through: Up to 8″

• Electric: 240/220V, 60/50Hz 240/220V, 60/50Hz

• FLC: 10 amps

• Air: 1.5 cfm, 80 psi

• Touch Screen: Funnel, Foot Switch, Guards

• Manual: 1 Year Parts Warranty Included

Advantages of collaborative robots

-Fast and easy robot deployment, even for small-volume production and fast change-overs

-Easy programming with no experience required

-Re-useable programs for recurrent tasks

-Lightweight for easy redeployment to different machines

-Safe for side-by-side human interaction with patented force-limiting technology

-Increased quality, consistency, and production speed

Have a questions? Fill out the form below and we’ll get back to you!

Click Here to Read More

Click to Learn About Robot/Cobot Hire in the UK.