Increase workplace productivity and reduce the danger of employee injury by investing in a collaborative robot (cobot) for CNC machine tending. CNC cobot machine tending will help increase workplace productivity by taking the place of human operators managing CNC machines 24 hours a day, seven days a week (if necessary).

Special Offer This Month

Free Installation and Training worth £1499 plus VAT FOC

(Enquire Below)

Cobots are useful for completing repetitive activities, especially when operating near heavy machinery where workers would perhaps be put at risk. Collaborative robots complete mindless, repetitive actions while employees can make better use of their time elsewhere in the business. You will no longer have to hire human operators to tend machines, which can help lower your operation costs and boost workplace morale.

Dull, repetitive and potentially dangerous jobs no longer need to be completed by human operators but can instead be achieved through the use of collaborative robots. Cobots work alongside human employees by tending and operating machinery, giving human employees the time to complete more meaningful and less repetitive tasks.

Cobots are autonomous, which entails that they work independently from humans; this means that minimal interaction or management is required in order for them to function correctly. Once a risk assessment is completed, cobots need little to no safeguarding other than periodic maintenance and repair, thereby allowing humans to get on with more valuable activities.

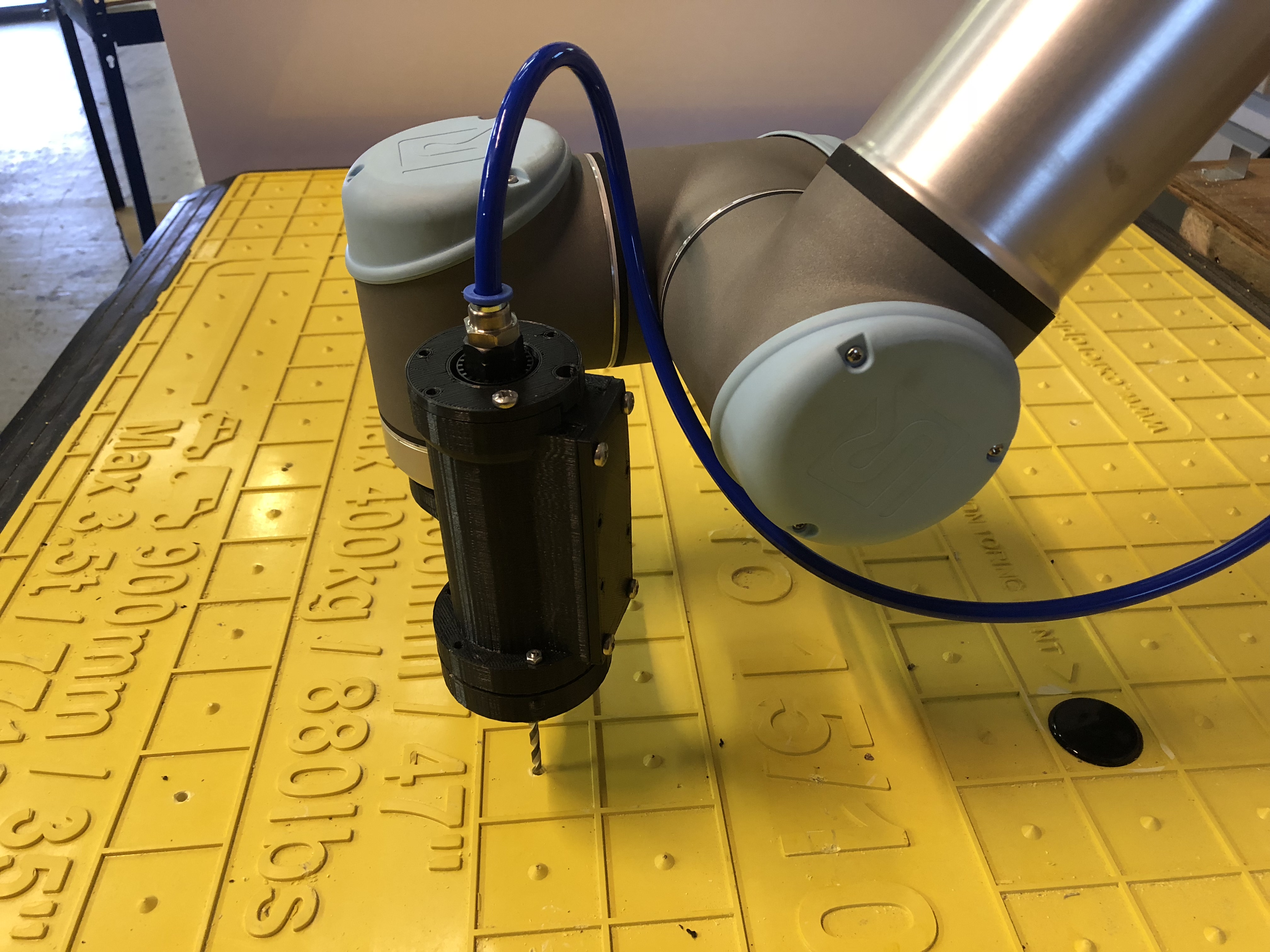

Collaborative robots help to increase efficiency and product quality by ensuring that repetitive and dull tasks are completed to the highest possible standard time and time again. Robotic arms are one type of cobot which can be used to automate nearly any job with proficiency and excellence.

Collaborative robots can be easily programmed to reuse a particular program for a recurring task, and applications can be scheduled in advance to save time and increase efficiency. One of the significant benefits of investing in a cobot to tend CNC machines is the reduced need for employee training of machine tending. This helps to reduce the costs associated with staff health and safety training and means that there will be less need to hire machine operators.

Collaborative robots help to free up time for human workers to complete higher-value tasks and reduce the likelihood of workplace accidents and repetitive strain injuries. Cobots also reduce production costs in the long run by diminishing the need for human-machine operators and workplace safety training. More money can be invested in the expansion of your business by hiring more employees in other areas of your company and purchasing more advanced machinery or additional collaborative robots.

Have a questions? Fill out the form below and we’ll get back to you!

Click Here to Read More

Click to Learn About Robot/Cobot Hire in the UK.